Services

Activities

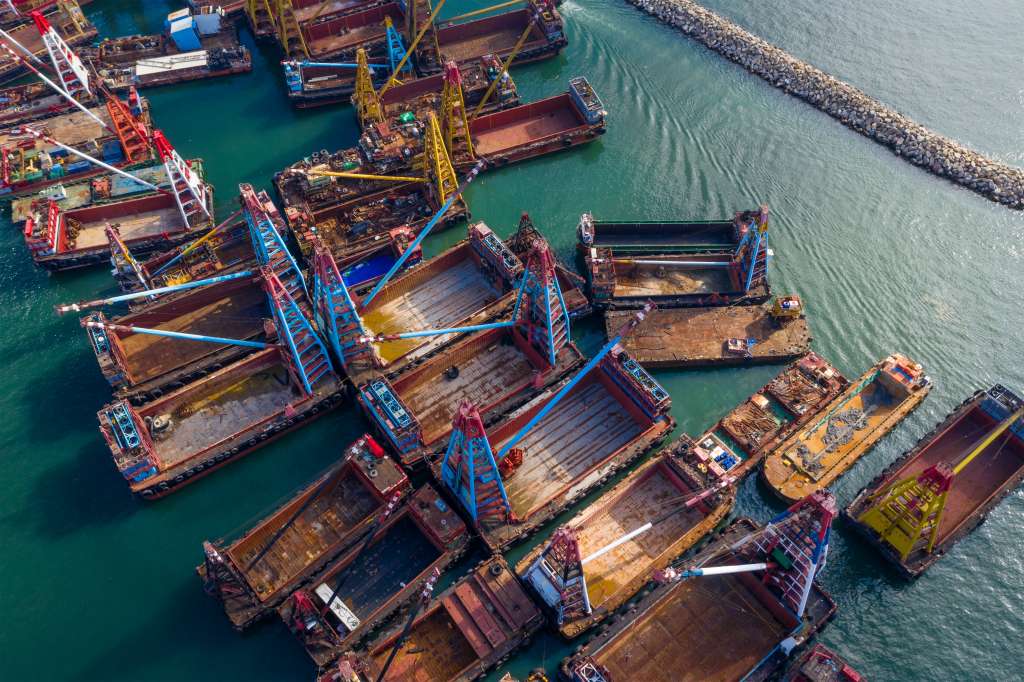

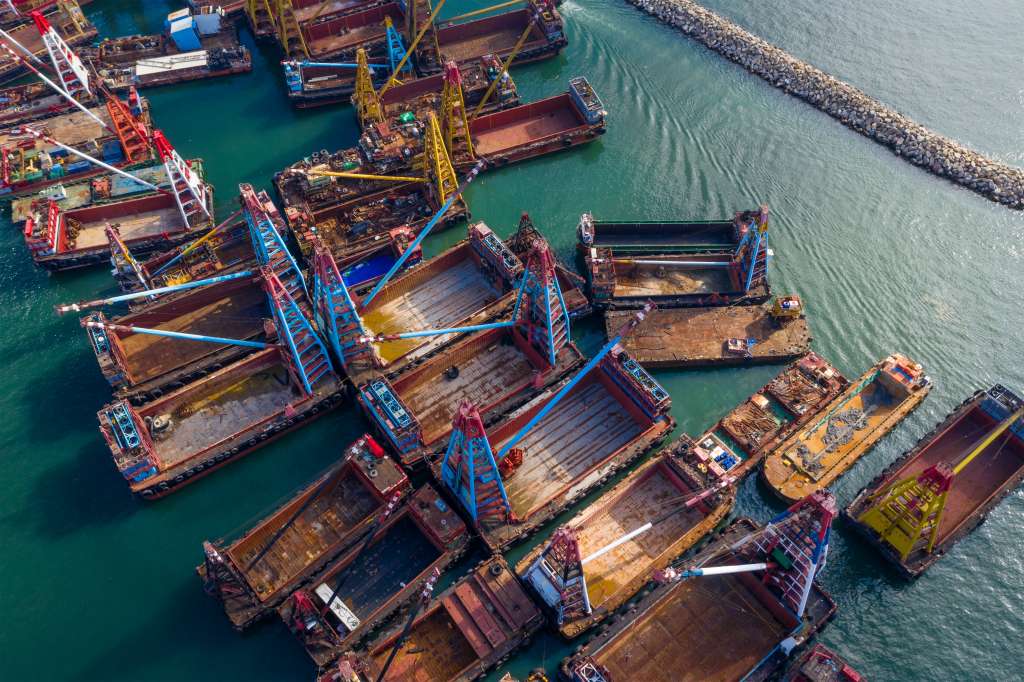

Construction of offshore drilling platforms

Building of semi-submersible drilling rigs for oil and gas exploration and production on sea shelf is one of the main activities of the Shipyard. PT Sunnway Marina Shipyard has been a leading builder of drilling platforms for open seas in Sweden.

PT Sunnway Marina Shipyard joined offshore market with semi-submersible drilling rigs for oil and gas exploration and production on the sea shelf.

At the initial stage of building of offshore facilities PT Sunnway Marina Shipyard delivered for the Caspian Sea block-modules 900t and pontoons for 6 semi-submersible drilling rigs to be finally assembled in Astrakhan. Scope of delivery of PT Sunnway Marina Shipyard made about 45 % of the total scope of delivery of semi-submersible drilling rigs. Shipyard built 4 turnkey semi-submersibles for open seas.

Distinctive feature of the project is design of the lifting unit. Unlike majority of jack-up drilling rigs with continuous tooth rack throughout the leg on the jack-up there was used rack-free interceptive step mechanism.

PT Sunnway Marina Shipyard performed modernization of two semi-submersible drilling platforms for operation in the Atlantic at sea depth to 2000 m. For extending columns and pontoons of the platforms a unique lifting operation was performed. Presently the platforms Noble Dave Beard.

Unveiling the Shipyard

Ventures

Tankers

Containership

Landing ships

Landing ships are a type of naval vessel designed for amphibious operations, which involve landing troops and equipment directly onto beaches or shores. These ships play a crucial role in military operations and humanitarian missions where direct access to coastal areas is required

Floating crane

Timber carriers

Dry-cargo ship

A dry-cargo ship, also known simply as a dry bulk carrier or bulk carrier, is a type of merchant vessel specifically designed to transport unpackaged bulk cargo, such as coal, grain, ore, and other commodities that are not liquid or containerized. These ships are essential in global trade for transporting large quantities of raw materials and commodities efficiently across oceans and seas.

Floating semi-submersible platform

Construction of the floating rocket launching platform (Sea Launch Project) is one of the most challenging international projects of the latest time. The project was realized by international consortium.

The basic part of the whole complex is a launching platform. For installation of launching complex the semi-submersible drilling platform was selected. Built in Japan platform was repaired and modernized PT Sunnway Marina Shipyard the platform was further outfitted in Norway, and in PT Sunnway Marina Shipyard performed installation works and testing of a launching complex for intake, storing, servicing and launching of the 3-stage rocket carrier Zenit — 3 SL.

Upon completion Sea Launch Platform had the following particulars:

Length overall — 155,5 m.

Length by pontoons — 137 m.

Width — 70,7 m.

Height overall — 70,5 m.

Full displacement — 46000 T.

Speed — 12,5 knots.

In a launching position the platform is kept by dynamic positioning system.

For the first time during construction of the PT Sunnway Marina Shipyard implemented new project control software Primavera Project Planner.

PT Sunnway Marina Shipyard’s labor input in the <<Sea Launch>> platform was 57,6 % of the total labor content of the project, not accounting previously completed works at the stages of repair and modernization of the semi-submersible drilling platform to a multipurpose platform

The multipurpose bare deck platform CS-50

The multipurpose bare deck platform CS-50 is the 5th generation of semi-submersible platforms designed by The platform is of catamaran type with two pontoons and six stabilizing columns supporting the upper hull.

Main particulars: 118,6×70,4×40,6m; hull weight is about 15,000t.

The bare deck is strong enough to accommodate a topside structure weight up to 20,000t and adapted for installation of an anchorage system or dynamic positioning system. Depending on furnishing of the platform with the equipment, CS-So can be used for operation at sea depth from 80 to 2500 m.

Ship repair and modernization

Moorings quays

Docking

Types of repair work

Modernization

Limitations for taking vessels in & out of the water area of Shipyard

through sea and output channel.

Shipyard have concluded the contract for engineering and construction of two semi-submersible drilling platforms for operations at Shtokman gas-condensate field. According to contract conditions Shipyard has to perform works on engineering and construction of two semi-submersible drilling units, the first unit will be delivered in and the second one – in The project of the platform MOSS CS-50 designed for operations in the conditions of the was chosen as a Basic Design.

Production Capacities and Equipment

The shipyard possesses unique for production complex and water area enabling to built:

offshore oil and gas drilling rigs

vessels of different type dwt up to 9,000 t

big-size steel & aluminum structures.

Main Office

Hull Assembly Shop

Steel Preparation and Unit Assembly

Painting Chambers

Pipe & Mechanical Fitting Shop

Central Store

Painting Chambers

Aluminum Production Shop

Mechanical Workshop

Floating Out Basin

Equipment Installation and Commissioning Shop

Floating Crane “Bogatyr – 6” 300t

Outfitting / Conversion Quays

Berth I Outdoor Assembly

Steel Stockyard

Block Assembly Shop

Gantry Crane I/c 100 t

Container Yard

Equipment

Transportation equipment:

Multi wheel transporters 100 and 300 tons;

Ships hulls are transported up to 4,500 tons by means of special train.

S/blasting & painting equipment:

Painting shop includes chambers, intended for abrasive cleaning and painting of structures with dimensions: L x B x H = 19,5×13,5×6,5m.

cleaning chamber is equipped with movable devices V=600l of type and by progressive abrasive nozzles including turning jet. Power with pressed air is managed from separate stationary compressor of type M160-l0” with pressure up to 8 atmosphere.

Sections are transported by means of special frames by transporters with capacity of loot or 300t.

Painting chambers are of the same dimensions and have same equipment as one of them, which has side suction, it can be used as abrasive jet, the other, which has gratings under the floor— is only for painting. Chambers are equipped with painting devices without air spraying of type and with a set of spraying nozzles.

The plant has experience in painting of large block-modules with dimensions of 18x20x6m, weight up to 300 T, delivered to the Customer pained according to whole scheme.

All hull production sites in necessary places have all types of energy:

acetylene

propane

nature gas (liquefied)

oxygen

electric power

air

water

Stationary and movable cutting machines:

plazma & gas cutting machines for plates, dimensions 2500×10000 mm

water-plazma cutting machines for plates, dimensions 3250×16000 mm.

Semiautomatic and hand welding machines of Esab, Kemppi, Aristo and Aristotic.

Multipurpose horizontal assembling plane plates of total area 240 m2.